Mass inoculation against COVID-19 has begun in several parts of the world. With the rise in demand for large-scale and urgent COVID-19 vaccine distribution, supply chain leaders must take this opportunity to urgently fill in the distribution barrier.

So, how do you analyze the best way to drive critical protocols and find the best practices related to COVID-19 vaccine resourcing or distribution? Well, the answer is simple. You need an agile and resilient service, centered on patient healthcare. But how will you achieve that? You will have to bring together vast amounts of data, insights, and advisories before deploying processes and technology solutions to make sure they’re the right balance of agility and efficiency in order to ensure last-mile fulfillment.

The points that you need to focus on include suboptimal logistics & transportation infrastructure, data communications network capabilities, security, local regulatory & trade management demands, and even local weather & temperature forecasts. But, you need to be careful not to forget that you’ve got to be robust and agile in order to be able to accommodate numerous shifting variables.

The pandemic has only added to the multiple layers of data insights. This has increased the scale, scope and volatility of information that supply chain leaders are receiving. Another point to consider while strategizing for an ideal supply chain for vaccine distribution would include global media visibility. This amplifies the urgency for a coordinated supply chain response in areas that have not previously encountered.

Use Disruptions as Catalyst

Even though new service responses might challenge the efficacy or resiliency of your practices, standards, and technology solutions that have been embedded as best practice in supply chains in recent years, a progressive supply chain leader shall be able to navigate and channel disruption as a catalyst in order to streamline new business responses because there might not be one ‘best in class’ standardized model of governance and testing across countries anytime soon.

As most companies are beginning to execute their plans and strategies across physical deployments, there will be opportunities to leverage early lessons and expertise that can help in translating and contributing to future phases of evolution in more responsive service models. The World Health Organization itself believes that the pressure to increase performance is pushing the limits of what can be achieved by supply chains. They also have the process for Immunization Supply Chain and Logistics explained in detail.

Lastly, here are some things you need to plan with all your attention in order to have the ideal supply chain for vaccine distribution:

Planning

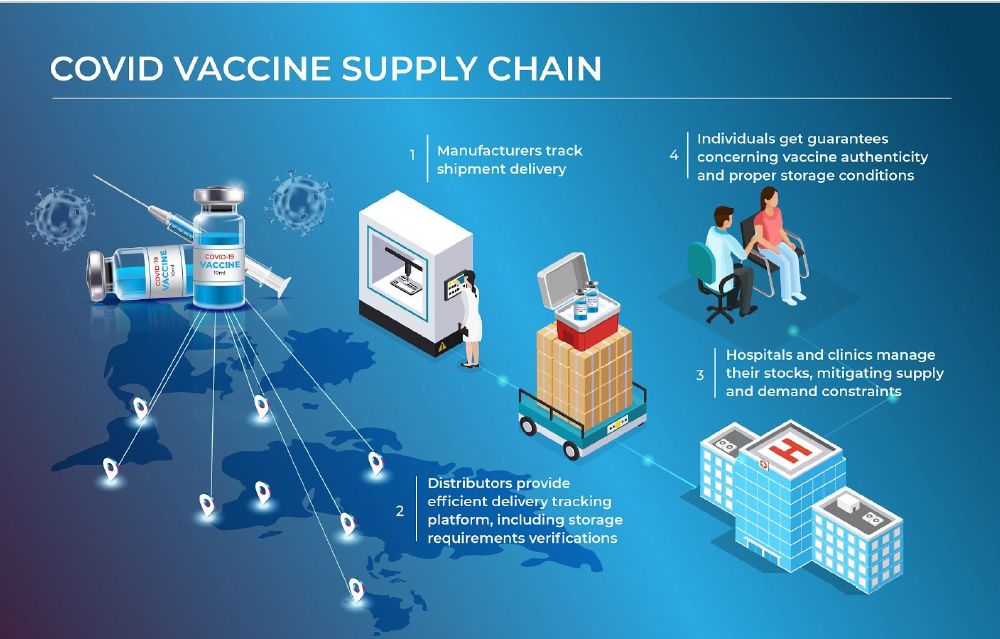

Good planning is necessary to understand the capacity of infrastructure and critical assets to be able to deliver effectively. Demand planning comes to the fore when millions of doses of vaccine are required. So, those responsible for procurement must swiftly evaluate different manufacturers of vaccines, syringes & refrigeration equipment, etc segmented according to their location, capacity, and compliance with licensing and other regulatory requirements.

There is also an option to use multiple manufacturers, considering the number of vaccines available and more that are possibly in the pipeline. And while it will help you in increasing the volume, it also adds to the complexity. Different products with different storage conditions and different expiry dates. Third-party logistics are most likely to fill in the gap for the high demand for the vaccine with the options of one or more providers for national, regional, and local deliveries. Appointing a lead provider can be an effective move, aside from robust inventory management, optimizing product flows, etc.

Temperatures

Controlling cold storage is an integral part of the new COVID-19 vaccine supply chain. The volumes of vaccines being produced and transported could expose limitations in refrigerated capacity in warehouses, vehicles, and healthcare facilities. An eye on the end-to-end temperature logging, as well as real-time monitoring and reporting of temperature, shock, and moisture, will also help in keeping the balance. You can use system alerts via automated scanners, etc.

Track and Trace

Visibility is vital for all supply chains, without any doubt. You can use the data to enable efficient tracking which will yield better demand planning, informed decisions on ordering, distribution, order allocation, storage & returns, optimizing product flows, and avoiding overload & wastage.

Product Integrity

Pharmaceuticals, just like all other supply chains, can be vulnerable to counterfeiting, tampering, contamination, and theft. This is why provenance and authenticity are critical, to assure safety and efficacy to end users of the vaccine. You can opt to serialize the batches for easy identification, with proof of pick-up, and delivery confirmed via an authenticated chain of custody, reported through smart, IoT devices and applications.

Last-mile Delivery, Returns, Post-vaccine tracking

Like we mentioned at the beginning, Last-mile delivery is one of the most critical parts of the COVID-19 vaccine supply chain. Vehicles that are assigned for last-mile deliveries must be equipped with cold chain storage and precious cargo facilities, commandeered by licensed drivers, and integrated into track and trace systems to assure 24/7 visibility for both delivery and returns.

For more significant posts like ‘Supply Chain for Vaccine Distribution’, connect with us on Facebook, Twitter, and LinkedIn.